Vacuum plates for handling jars

The PMP vacuum plate

The PMP type vacuum plates are used for palletizing or depalletizing containers. It is suitable for all type of vacuum heads and available in many materials, dimensions, thicknesses, hardnesses, etc.

User / use

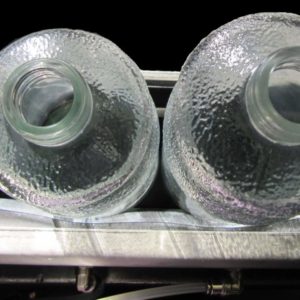

Bottling: (De)palletization of jars

Container manufacturers: (De)palletization of jars

General industry: (de)palletization of other containers (plastic containers, PET…)

Technical characteristics

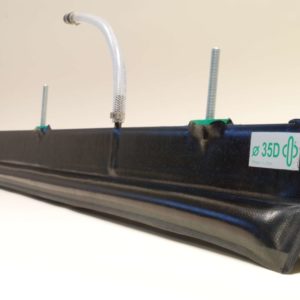

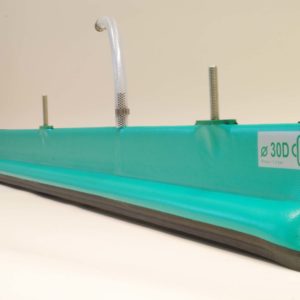

Our vacuum plates are manufactured with a foam substrate covered by a polymer layer. This foam is bonded to a wood support. Other types of support are available upon request.

The plate must be mounted perfectly on the vacuum head, which is why we offer several dimensions on request.

The standard thickness of our vacuum plates is 21mm (foam + coating). We can also provide other specific thicknesses.

Performance

Our vacuum plates are quick to change and are adaptable to all your supports and pallet layouts.

We can also supply a complete vacuum head, according to your technical specifications.

If you wish, we can supply a plate perforated according to your pallet layouts.

Composition

The vacuum plate is divided into several areas:

- A wood support (or other material on request)

- A foam plate bonded to the support

- A rubber top coating

Customisation

Our engineering office creates products tailored to your needs. We offer fully custom-made vacuum plates. You can choose the dimensions of the support and the foam for the plate to have a perfect fit with your vacuum head.

We also offer various options to equip your vacuum plates: other support than wood (PVC for example), bakelite-coated wood to prevent the wood from decomposing, sealing strip to provide a seal between the plate and the vacuum head, silicone contour around the foam to improve its performance and air tightness, food contact certified coating for production subject to sanitary standards, maximum layer on the entire surface of the plate for better sealing, aluminium profile to secure the maximum layer, adhesive strip on the foam (if we only supply a foam plate).

Do not hesitate to share with us your various problems (limited footprint, specific devices, specific pallets, etc.). We will adapt our grippers to conform with your installations and requirements.

We also offer studies to optimise your processes while taking your constraints into account, which will help you optimise your production while adapting to your installations. We can also respond on your site on request.

Why choose Simtech vacuum plates?

Simplicity of use | saves time | saves space | profitability | adaptable to your installations | production flexibility (plates for all jar formats) | Low maintenance

Why choose Simtech quality?

We are manufacturers and ISO 9001: 2015 certified | We have qualified staff | We export our products worldwide

We have more than 25 years experience in our field