Laminating vacuum bag for high temperature Oven or Autoclave use – OBSJ

The ABSJ/OBSJ vacuum bag

Laminating vacuum bag for high temperature comes in the form of a flexible envelope equipped with a simple, fast and airtight closure system as well as a vacuum exhaust system over its entire internal surface. It is reusable. It allows for optimal application of vacuum and withstands high temperatures in the oven or Autoclave.

User / use

Architectural industry: for creation of glass steps, safety railings, acoustic glass, anti-UV glass, balustrades.

Military industry: bullet-proof laminated glass.

Composite industry: compacting and crosslinking of pre-impregnated composite plies.

General industry: LCD screen, photovoltaic panels, vacuum bonding.

Technical characteristics

The Laminating vacuum bag for high temperature and accessories are vulcanised in bulk (automobile tire manufacturing process), which gives them very high strength and excellent flexibility.

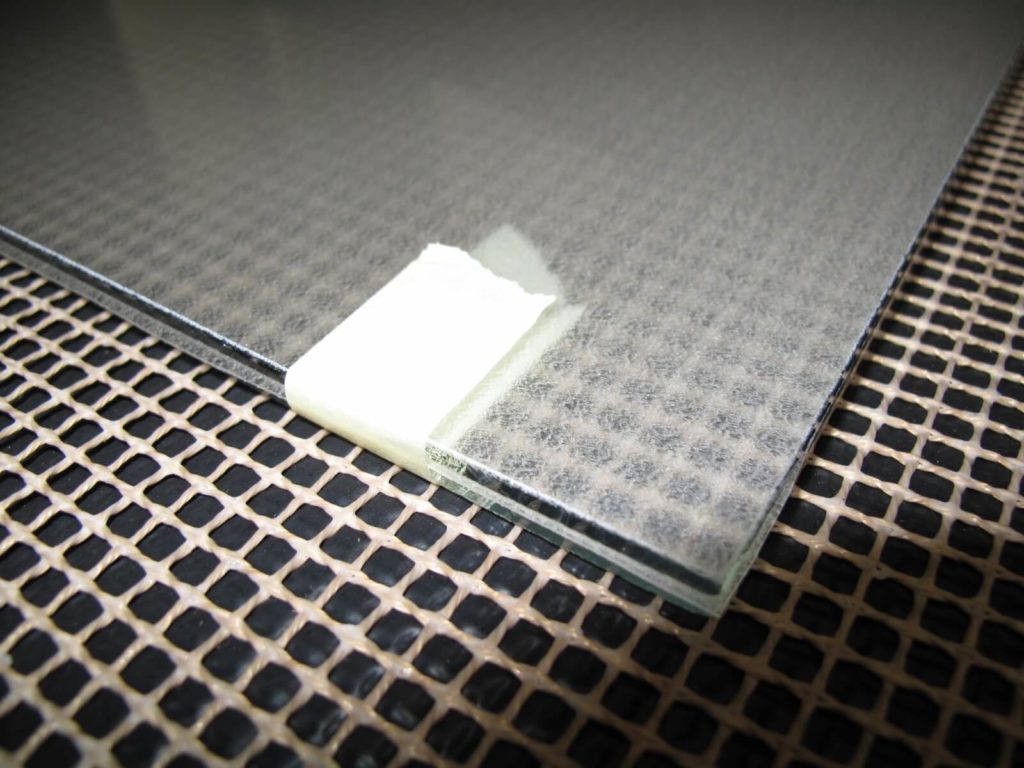

They are closed and sealed by a rubber gasket with a clip.

The anti-stick internal coating can be cleaned. This neutral coating does not adhere to any interlayer and pollution, avoiding production residue and repeated cleaning.

Performance and benefits

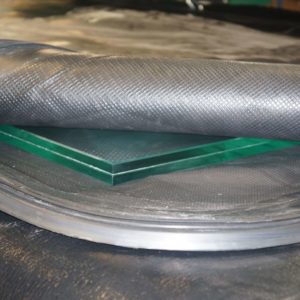

OBSJ/ABSJ vacuum bags can be used in manual laminating processes that are flat, with significant curvatures, contain perforations, added elements, of varying sizes/thicknesses, of irregular shape as well as multi-layer complexes.

The maximum temperature of use for this model of bag is 200°C / 392°F.

The bags are designed to withstand an optimal vacuum of -0.99 mbar.

The quick and simple closure system makes it possible to limit handling time and to avoid scratching the glass.

They can be used horizontally on a trolley or table.

The vacuum bag has been specifically developed to provide excellent thermal conductivity and thereby limit the cycle time.

The interior of the ABSJ vacuum bag is fully covered with an anti-stick material that avoids adhesion of the interlayer (or resin) and therefore does not “pollute” the following parts. It is a versatile laminating and deairing tool, robust and with a very long life span.

Its flexible design allows for quick folding along the vacuum channel, limiting storage space required.

The use of reusable vacuum bags makes it possible to limit the ecological footprint and reduce production costs by depreciation.

Composition

The bag is divided into 3 areas:

- Its glass processing area is optimal and uniform.

- Its gasket type closure system provides maximum closure and sealing.

- Its exhaust system has a Ø10 notched vacuum socket.

Customisation

Our vacuum bags are made to measure, and our engineering office therefore can develop a bag according to your recommendations. We can make vacuum bags up to 20000X20000 mm including your technical specifications. Do not hesitate to share your problems with us (storage, environment, temperature, positioning in the furnace). We will add eyelets, fastening tabs for vertical bags, marking, specific vacuum fittings, sheath for lifting strap, exhaust grill, etc.

Simtech can carry out process optimisation studies incorporating your constraints and allowing you to optimise your production and adapt to your installations. These studies can also be carried out on your site.

Why choose Simtech vacuum bags?

Simplicity of use | save time | save space | profitability | interior coating suitable for glass | production flexibility (several glass dimensions in the same bag) | low maintenance

Why choose Simtech quality?

We are manufacturers and ISO 9001:2015 certified | We have qualified staff | We export our products worldwide

We have more than 25 years experience in our field