Edging for filtration and sieving grid

In general, sieving is a crucial operation in the hygiene of finished products. It is used in the processing of foreign bodies in high added value industries. It allows for a high quality finished product.

Filtration and sieving are techniques widely used in the agri-food, chemical and pharmaceutical industries. Indeed, filtration is a process that enables separation of the constituents of a mixture that has a liquid phase and a solid phase through a porous medium.

The use of a filter makes it possible to retain particles of the heterogeneous mixture which have a larger size than the filter orifices.

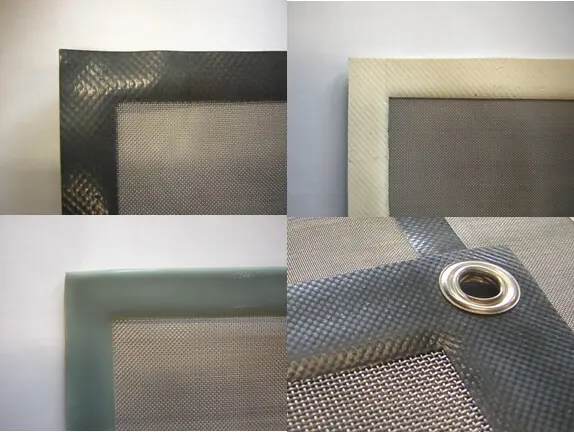

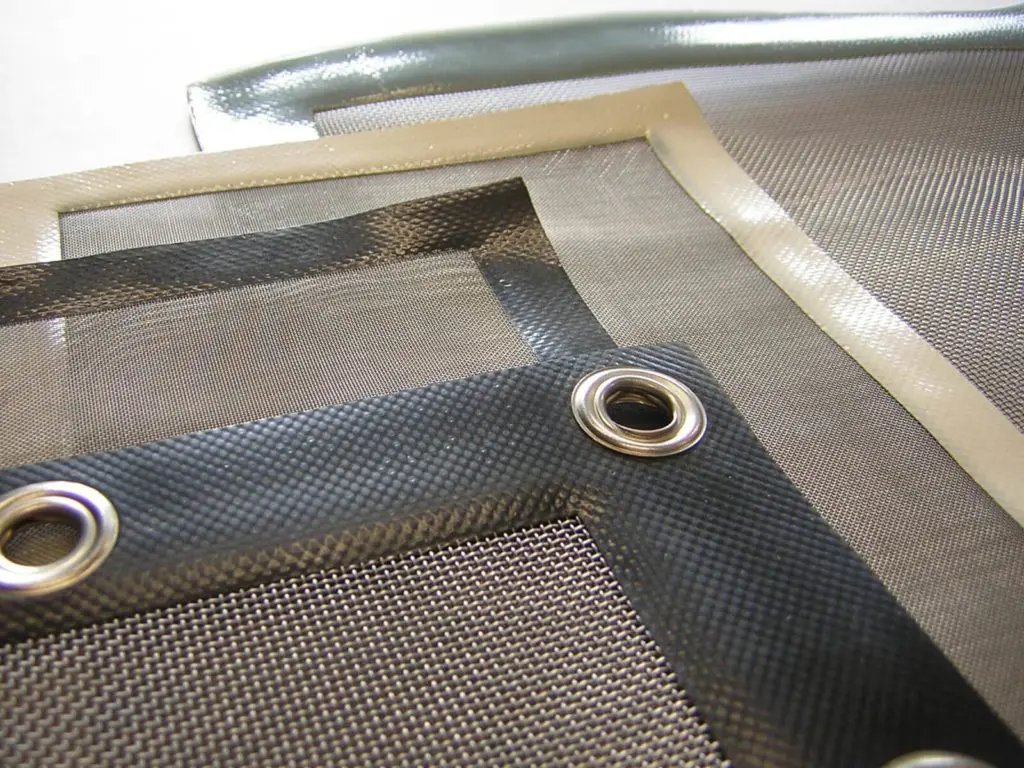

If you are a manufacturer of fabrics and wire cloth in the filtration and industrial screening sector, Simtech offers within its Flexfilt® line the possibility of affixing a synthetic rubber edging on metal fabrics and woven metal mesh. This rubber edging protects sections and joints. These contours create a non-cutting edge that also allows for sealing and easy mounting on the supports (piercing and clamping). This edging is offered in rubber with various properties: food contact, drinking water contact. We can also offer an abrasion resistant and chemical resistant non-stick surface coating for specific applications. The edging is affixed under pressure on the wire cloth for durable holding to withstand industrial, repetitive and demanding use. We have the possibility of providing you with these coatings in various thicknesses according to your specifications (use environment, ETC.). We can also supply edgings with piercing options, eyelets and fastening inserts, etc.

Do not hesitate to contact us for any additional information.