3D Design – Studies – Laboratory Testing – Qualification – Prototyping

Our technical department develops new solutions from our standard products as well as for your new problems.

Simtech has the necessary skills that allow it to carry out “custom” studies in many fields of activity. These studies lead to fabrication of a prototype, pre-production or directly to mass production of a product.

In order to carry out the new designs entrusted to us, we continually improve our skills in many areas including:

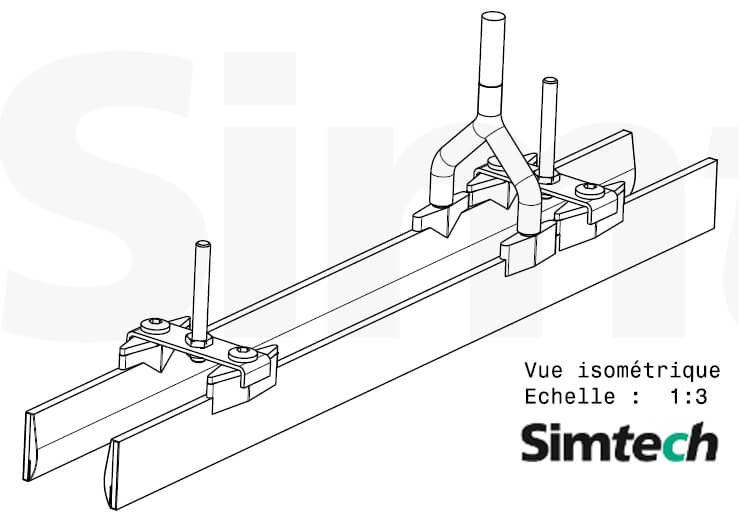

- Mechanical design

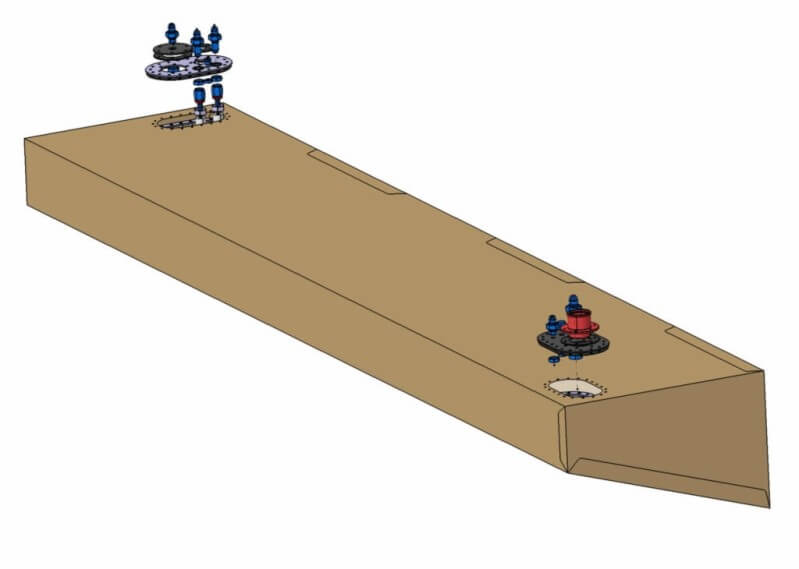

- Design and creation of thermal control systems

- Formulation and transformation of polymers

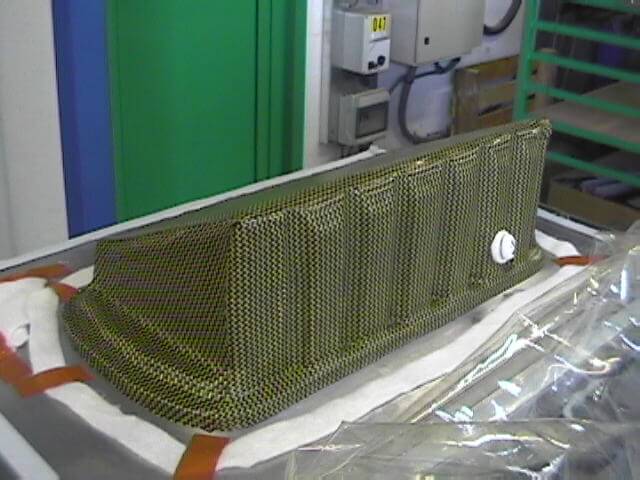

- Design and creation of coated technical textiles

- Design and fabrication of flexible waterproof structures

- Design and creation of vacuum applications

- Design and creation of storage and fuel transfer systems

Our engineering team can assist you in many activities within your field of expertise:

- Product and process technology monitoring and evolution

- Technical assistance services for repair, maintenance and installation of products

- Spare parts supply service

- Technical expertise and assistance with creation of functional specifications

- Training in installation, use and maintenance

Our ambition is to provide an effective and respectful solution for sustainable development that responds to the problems of flexible sealing.

To do this, Simtech has high-performance software resources (CATIA, SOLIDWORKS).

We have an inspection and development laboratory (rheometer, dynamometer, pulsation bench, cryogenics tests, …)